Why is GATE bio fertilizer granulator advance and the newest?

In recent years, with the rapid development of the organic fertilizer industry supported by national policies, people have a deeper understanding of the efficacy of organic fertilizer, and the production demand is increasing, which leads to the gradual increase of bio organic fertilizer manufacturers.Henan GATE heavy industry technology co., LTD., specializing in organic fertilizer equipment manufacturing, welcome new and old customers to inquire.

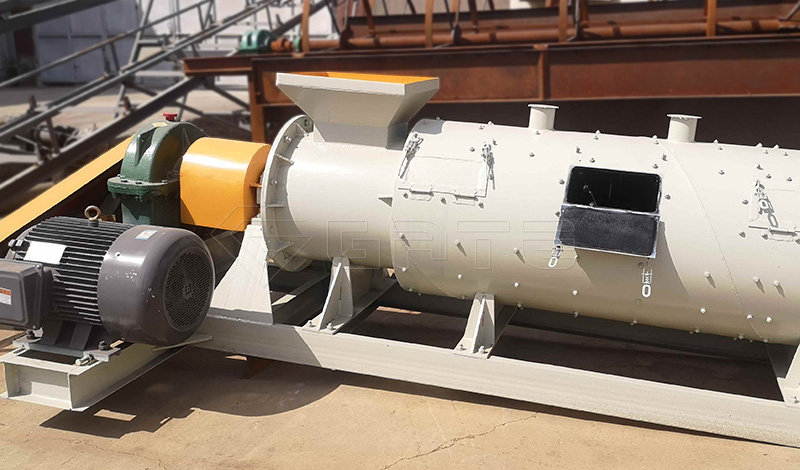

1.New compound fertilizer granulator

Widely used in granulation of organic fertilizers and inorganic fertilizers.As a result of granulation rate more, smooth operation, equipment rugged and durable, long service life, and is chosen by the majority of users as the ideal product.My unit inside and outside the development and production of rotary stirring tooth fertilizer granulator varieties Φ 600 Φ, 800, 1000, 1200, 1500, a variety of specifications, can also according to user requirements, development and production of other specifications of the inside and outside the stirring tooth granulator.The shell of granulator is made of thickened seamless steel pipe, which is durable and never deforming.In addition, the stable base design makes it run more smoothly.Two: working principle

Using the high speed rotating mechanical stirring force and the resulting aerodynamic force, the fine powder in the fertilizer granulator machine continuous mixing, granulation, spherification, extrusion, collision, density, polishing and other processes, so as to achieve the purpose of granulation.Particle shape is spherical, sphericity ≥0.7, particle size is generally between 0.3-3 mm, granulation rate ≥90%, grains

The size of particle diameter can be appropriately adjusted through the material mixing amount and spindle speed, usually the lower the mixing amount, the higher the speed, the smaller the particle.

Application: this machine is especially suitable for granulation of light weight fine powder materials, and more suitable for granulation of organic and inorganic compound fertilizer.The finer the basic particles are, the higher the sphericity of the particles and the better the quality of the spheres.It is generally required that the particle size of materials before fertilizer granulation should be less than 50 mesh. Typical application materials: chicken manure, pig manure, cow manure, carbon black, clay, kaolin, nitrogen, phosphorus, potassium and other organic compound fertilizers and inorganic compound fertilizers are all suitable.

My company development and production of fertilizer pellet machine is in the stirring tooth pelleting machine, rotary drum granulator principle of manufacturing technology, on the basis of meticulous research and repeated experiments, the machine room temperature production bacteria, structural design is reasonable, it can produce round ball type of grain products, produce the grain moisture content is low, easy drying, high molding rate, particle strength, appearance and other characteristics, is the ideal of biological organic fertilizer, organic inorganic fertilizer, organic fertilizer granulation and inorganic fertilizer granulation equipment.The adaptive range of the granule:

Peat, sludge, chicken manure, livestock manure, lignite, sugar mill sludge, paper sludge, wine, straw, bean residue, peat and other organic waste can be directly pelleted after fermentation treatment, which completely solves the key technical problems difficult to solve by traditional disc (drum) pelleting technology, such as fermentation.

2.New granulator for organic fertilizer

The new type of granulator of organic fertilizer is also known as inner turning gear granulator which is widely used for granulation of organic fertilizer.As a result of granulation rate more, smooth operation, equipment rugged and durable, long service life, and is chosen by the majority of users as the ideal product.My unit the development and production of variety of dantian type tooth organic granulator is Φ 600, 800, 1000, 1200, Φ Φ Φ Φ more than 1500 kinds of specifications, can also according to user requirements, development and production of other specifications of the stirring tooth granulator.The shell of granulator is made of thickened seamless steel pipe, which is durable and never deforming.In addition, the stable base design makes it run more smoothly.Working principle: the new granulator of organic fertilizer makes use of the mechanical stirring force of high speed rotation and the air power generated from it, so that the fine powdery materials in the machine continuously achieve mixing, granulation, spherification, densification and other processes, so as to achieve the purpose of granulation.The particle size is spherical, the degree of sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, the grain formation rate of fertilizer granulator is ≥90%, the size of the particle diameter can be appropriately adjusted through the material mixing amount and spindle speed, usually the lower the mixing amount, the higher the speed, the smaller the particle, and vice versa.Application: this machine is especially suitable for granulating light and fine powder materials.The finer the basic particles are, the higher the sphericity of the particles and the better the quality of the spheres.It is generally required that the particle size of the material before granulation should be less than 200 mesh. Typical application materials: chicken manure, pig manure, cow manure, charcoal, clay, kaolin, etc. Special application in granulation of organic fermentation fertilizer with organic manure and urine, compost, green manure, sea manure, cake manure, peat charcoal, soil manure, three wastes, microorganisms and other municipal solid waste, the particles are irregular pellets.The qualified granulation rate of this machine is up to 80-90%, suitable for various different formulations, the compressive strength of organic fertilizer is higher than disc and drum, the rate of large ball is lower than 15%, the particle size uniformity can be adjusted by the stepladeless speed regulation function of this machine according to user requirements.This machine is most suitable for direct granulation of organic fertilizer after fermentation, saving drying process and greatly reducing manufacturing cost.

Leave a Messages