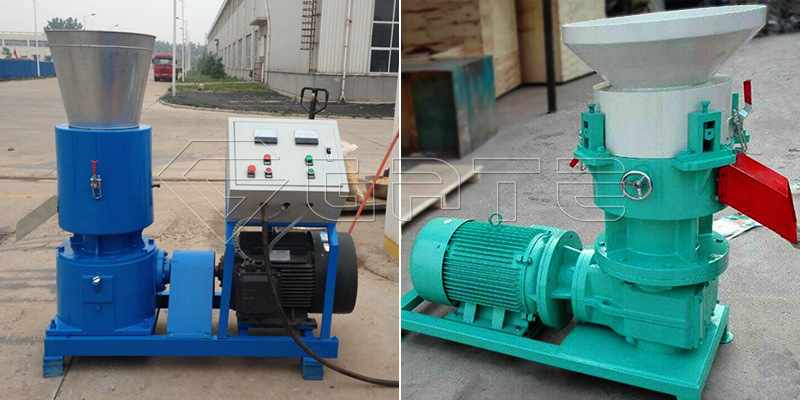

Why choose Flat die Granulator to produce organic fertilizer?

There are many types of granulators for manufacturing organic fertilizer granules, such as pan granulator, drum granulator, twin roll granulator, but flat die system.Granulators are becoming more and more popular. why?

That’s because the flat die granulator has many advantages.

1) High yield. More than 90%.

The flat granulator can be granulated up to 100%, and all raw materials can be made into pellets. Produce uniform spherical particles in one go,Less material.

2) Uniform spherical particles with a narrow particle size distribution.

The flat die granulator can easily control the diameter of the particles. As long as the diameter of the ring mold is changed, particles of different sizes can be produced To meet your own needs.

3) Good hardness and strength enough for packaging.

The pellets will remain in the shape of a sphere during storage and transportation and will not collapse because the flat die granulator has good compression ability.

4) Easy to operate and maintain.

The workforce does not need skills or experience. It is only necessary to adjust the water content of the raw material before the granulation process of the flat die granulator.

5) No adhesive material is required.

The flat mold granulator has an organic content of up to 100%, which is a true pure organic material granulation.

6) Save energy consumption

Since the required moisture content is 30-35%, there is no need to dry the raw materials before granulation. Flat mold granulator water during granulation.The fractional content is reduced, so drying costs can be saved.

7) Flat die granulator has stable operation, high efficiency and high productivity….

Leave a Messages