what the customer need to do to establish an organic fertilizer production line?

proposals and tips to establish a new organic fertilizer production line. Gate Technology provide professional proposals on how to establish a new organic fertilizer production plant. firstly, customer to need to have a marketing research on the fertilizer, what kind of fertilizer do you want to produce? organic fertilizer, or npk fertilizer or compound fertilizer? secondly, customer should have organic raw materials supply from farm. Thirdly , customer need to have budget investment on the organic fertilizer machine. Fourthly, Gate will provide whole organic fertilizer production process, and provide technical support for the installation and commissioning of the organic fertilizer manufacturing plant.

how to produce organic fertilizer from organic fertilizer production line?

-

Organic Material Fermentation

organic compost fermentation turner is used for fermenting and composting organic waste, such as animals & fowls manure, sludge waste, sugar filter mud, oil seed residues and straw sawdust etc. Materials can be mixed and fermented in the trough for 7-10 days. Temperature should be in 60-70℃ and moisture content should be between 40-50%.

-

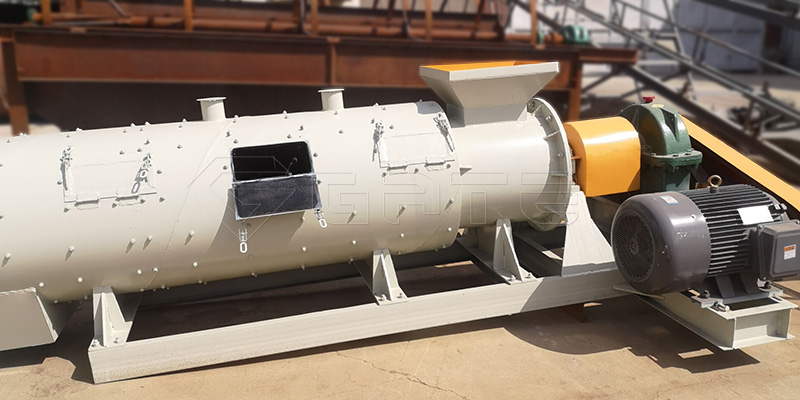

Raw Materials Mixing Machine

Fermented materials are mixed evenly together in horizontal mixer to improve fertilizer nutrient distribution uniformity and the greatest fertilizer nutrient use efficiency, which is also helpful for further granulating. The horizontal mixer machine is also suitable for feed, concentrated feed and additive premix mixing.

3. Organic Fertilizer Granulation MachineEvenly-mixed raw materials are transported into organic fertilizer granulator machine organic fertilizer pan granulator /disc granulator machine for pelletizing. The granules shape of organic fertilizer granulated by fertilizer pellet mill is round ball shape. Usually, a fertilizer polishing machine, which is designed based on flat die extrusion granulator, is used to polish the granules into ball shape with easy operation.

4. Organic Fertilizer Drying & Cooling processThe aim of drying process is to dry granules moisture, to increase fertilizer strength, convenient to store. After drying, the granules temperature is 60-80℃. due to too much heat, caking of fertilizer granules is easy to occur, so they need to be cooled in rotary drum cooler to decrease the temperature, After cooling, the granules temperature is 20-40℃, easier to storage and transportation.

5.Organic Fertilizer Grading & Coating & Packaging machineUnqualified fertilizers are screened out to re-granulate, while qualified ones are coated to increase the brightness and roundness of finished products, and then packaged for further storage.

Technical Data of 20,000 tons/year Organic Fertilizer Production Line

Item Name Model Overall Dimensions L x W x H(mm)

Prod. Capacity (t/h)

Power (kw)

Qty (set)

Vertical Crusher LF-600 1300X750X1900 3-5 22 1 Mixer Machine WJ-9015 2350X1200X1000 3-5 11 1 Pan Granulator YZ-2500 2900x2000x2750 3-5 15 2 Fertilizer Polishing Machine

PY-1000×2 2200x1050x1300 3-5 11 1 Rotary Drum Dryer HG1212 12000x1860x1600 3-5 7.5 1 Rotary Drum Cooler LQ1010 10000x1660x1400 3-5 7.5 1 Rotary Screening Machine

GS1240 5000x1600x2300 3-5 5.5 1 Rotary Coating Machine BM1240 4000x1400x1900 3-5 4 1 Automatic Packager DCS-50 3-8bags/min 3 1 Belt Conveyor 24 8 Dust Settling Chamber Drawing is provided 1 Hot Air Furnace Drawing is provided 1 NOTICE: This production line is for your reference only. Engineers and sales persons will specially design for you in accordance with your raw materials, self construction of factory building and capital budget.

what we can produce from the organic fertilizer production line?

You can make full use of the organic wastes to produce both powdered organic fertilizer or organic fertilizer granules and organic fertilizer pellet. The capacity of organic fertilizer production line or organic fertilizer production plant ranges from 1 ton/hr to 50 ton/hr, from small to large capacity for your choice.

Leave a Messages