What is the shape of the fertilizer granules for the roll granulator?

LANE Heavy Industries specializes in the production of various types of double-roller granulators. The improved double-roller granulator roller skin, mold and accessories are all made of 304 stainless steel. After high temperature quenching, annealing and other processes, the diamond impregnation technology is used, and the service life has been increased several times. The roll-rolling granulators produced by our factory are on the price, the manufacturers directly supply, avoid intermediate links, and refuse to make a difference!

Working principle of the roll granulator

The double-roller granulator belongs to the extrusion slip model. Its working principle is that the motor drives the belt and the pulley, transmits it to the active shaft through the reducer, and synchronizes with the passive shaft through the split gear to work in opposition. The material is added from the feeding hopper, extruded by rollers, demoulded into balls, and passed through a pair of chains, transferred to the crushing and sieving studio, sieved and separated the finished particles (balls), then the returned material is mixed with the new material, and Perform granulation. With the continuous rotation of the motor of the roll granulator, the continuous entry of materials can achieve mass production.

How does a roll granulator get fertilizer granules of different shapes?

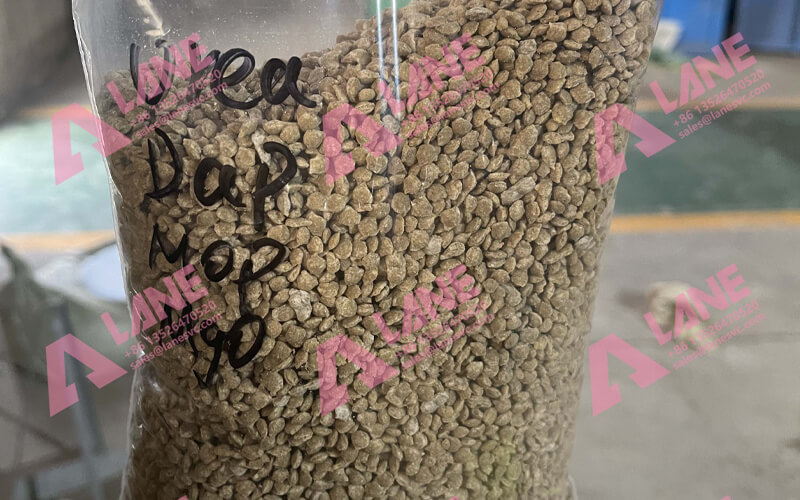

There are two types of extrusion for the roll granulator: front discharge and side discharge. The matched material is poured from the top of the counter-roller granulator. The groove has a vertical spiral rod. Through the rotation of the spiral rod, the material is forcibly sent to the bottom double rollers for extrusion. The relative rotation of the rollers makes the material sent into a pie shape, and the pie-shaped strips enter the granulator and are crushed by the rotary blade row. The broken material enters the rolling blade row of the counter-roll granulator, so that the particles and part of the powdery material enter the rotary blade Screen with shaker. By changing the grooved form of the roller surface, fertilizer particles such as flakes, strips and oblates can be obtained.

Leave a Messages