What is the difference between the Disc Granulator and the Roller Granulator?

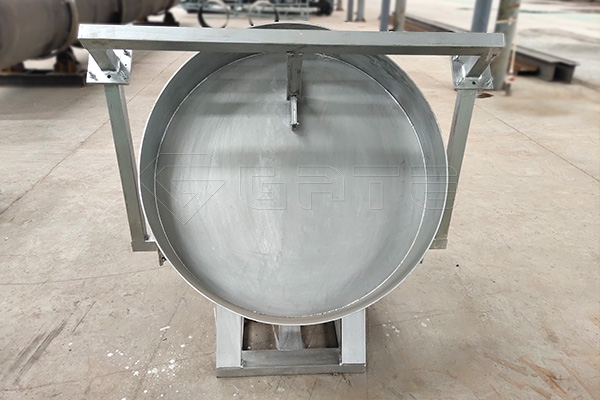

Disc Granulator

It is a new type of inclined disc granulation equipment, and the granulation disc

angle adopts an integral circular arc structure. The granulation rate can reach more

than 93%, the granulation tray has three discharge ports, the reducer and the

motor are driven by a flexible belt, which starts smoothly, slows down the impact

force and improves the service life of the equipment. The radiant steel plate is

reinforced, durable, non-deformable, thickened, weighted, and sturdy. It does not

require anchor bolts for fixed operation. The main gear of the granulator is high-

frequency bonfire and the service life is doubled. Granulation After anti-corrosion

treatment, the disc is durable. The machine has the advantages of uniform

granulation, high sphericity, stable operation, sturdy and durable equipment, long

service life, etc. It is highly praised by users and is an ideal product for users.

Disc Granulator working principle

The pulley and the belt are driven by the main motor, and the pinion gear is driven

by the reducer. The pinion gear interacts with the large gear fixed at the bottom of

the disk. The large gear is specially designed and mounted on the spindle fixed on

the frame adjustment plate to support After the whole granulation disc work (the

machine is used in the spray machine), the material enters the disc granulator, and

the granulation disc is continuously rotated and sprayed to make the materials

evenly stick together to form the spherical granules. The upper part of the machine

granulator is designed with an automatic material clearing device to prevent the

material from sticking to the wall, thus greatly improving the service life of the

machine. With the continuous rotation of the motor and the continuous entry of

materials, mass production can be realized, and continuous operation has been

achieved.

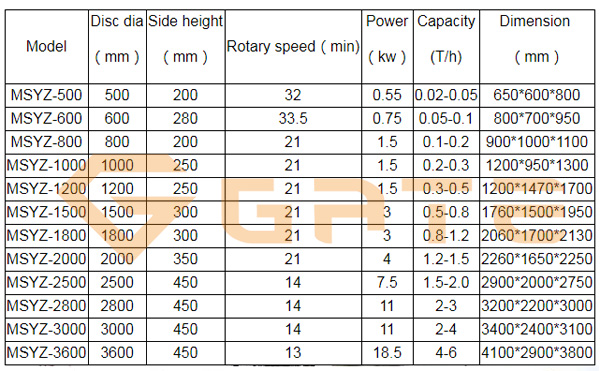

Technical Parameter of Disc Granulator

The Roller Granulator

The roll extrusion granulator is a widely used granulator in the organic fertilizer

granulator. The design of the roll extrusion granulator is very reasonable, very

practical, and has low energy consumption. It can be continuously produced

without the need of drying at room temperature. The ball and socket on the roll

skin can be manufactured according to the size and shape of the customer. The ball

hopper of the pair of roll granulators has a spherical shape, a pillow shape, a semi-

circular shape, a rod shape, a pill shape, a walnut shape, a flat ball, a square bar

shape and the like. Now a new energy-saving product for the compound fertilizer

and organic fertilizer industry.

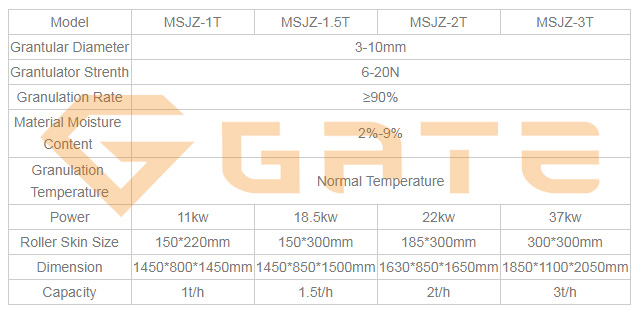

Technical Parameter of Roller Granulator

Advantages of the Roll Granulator

1. Energy saving and consumption reduction. Compared with other methods, no

drying measures such as fuel and gas are required.

2. No need to add additional adhesive, just use the intermolecular force of the

material itself to simplify the process and reduce energy consumption.

3. The investment is low.

4. The material composition is flexible, and a set of equipment can produce more

than 30 kinds of formula products.

5. Green environmental protection has no three wastes, and the basic national

policy to adapt to environmental protection is also in line with the development

strategy of environmental protection.

Leave a Messages