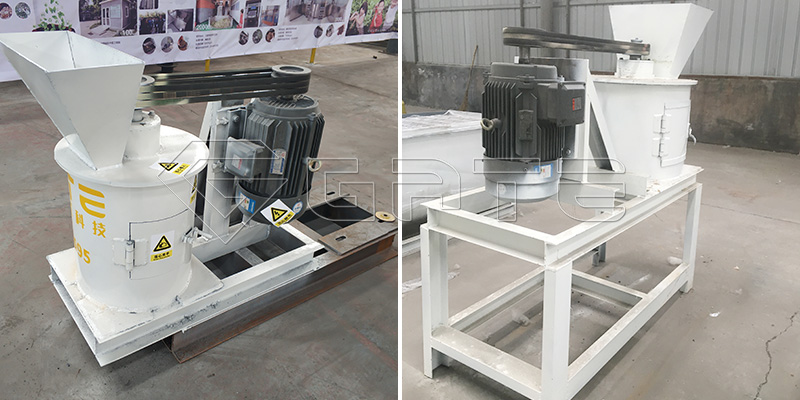

Vertical Chain Crusher Used for Phosphate Fertilizer

Technical parameters of vertical chain crusher

| Model | Maximum size of entering graule (mm) | Outlet Size (mm) | Motor power(kw) | Prod capacity(t/h) |

| LP500 | ≤60 | <3-5 | 11 | 1-3 |

| LP600 | ≤60 | <3-5 | 11 | 1-5 |

| LP800 | ≤60 | <3-5 | 15 | 2-8 |

Brief Introduction of Vertical Chain Crusher Usually Used in Phosphate Fertilizer

The long-term use of GATE vertical chain crusher proves that the machine is easy to use, high in efficiency, large in production capacity and simple in maintenance. The vertical chain crusher is suitable for crushing various block fertilizers and other medium hardness block materials. The chain crusher is capable of pulverizing 14% of undried water, phosphate phosphate containing 6% free acid and various phosphate compound fertilizer products.

Running Principle of Vertical Chain Crusher Usually Used in Phosphate Fertilizer

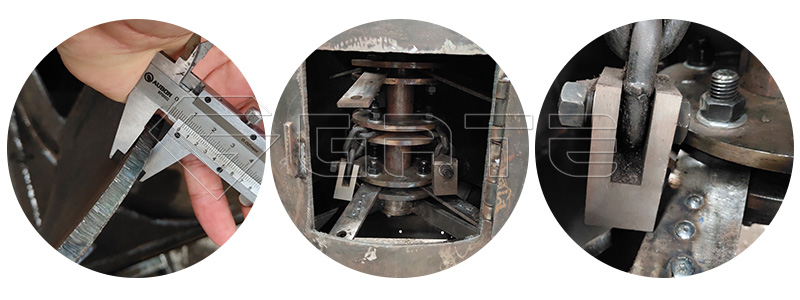

The vertical chain mill is a single rotor and the horizontal chain mill is a double rotor. The main working parts of the chain mill are the rotors with steel ring chains, one end of the chain is connected with the rotor, and the other end of the chain is equipped with wear-resistant steel ring chains. The vertical chain mill belongs to impact mill, which smashes the impact of material block by high-speed rotating chain.

Characteristics of vertical chain crusher commonly used for phosphate fertilizer

1. Vertical chain crusher has reasonable design of inlet and outlet, suitable for particle crushing below 60mm, compound fertilizer production of block material and other large materials.

2. The vertical chain crusher is easy to clean, the design of the import and export is reasonable, the broken materials are even, and it is not easy to stick to the wall.

3. The vertical chain crusher has a reasonable structure, and the chain crusher comprises a semi-closed casing as a crushing chamber and an upper side of a feeding funnel casing connected thereto.

Leave a Messages