Solutions

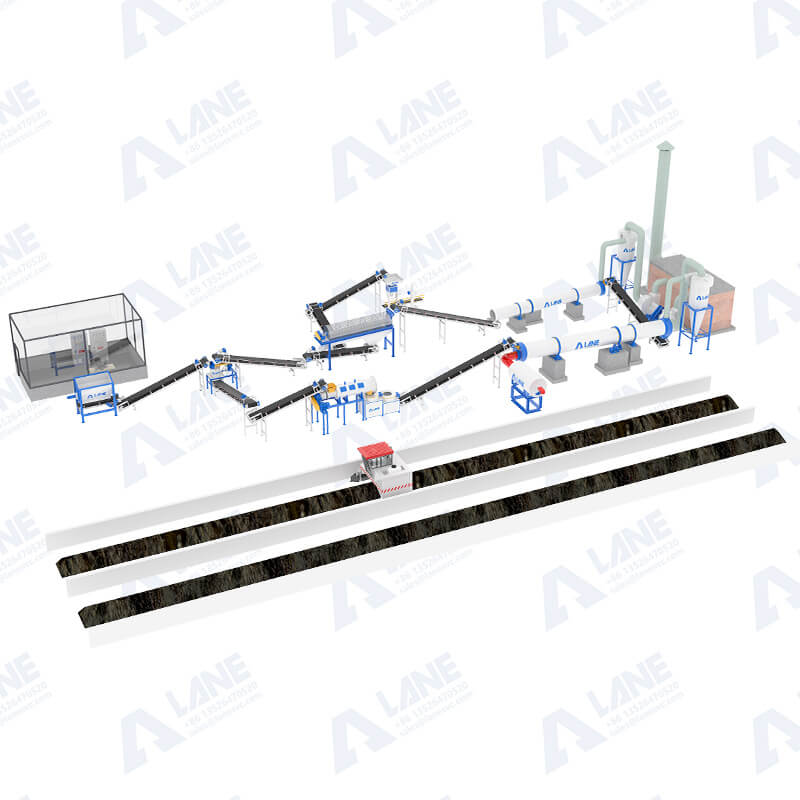

Animal manure organic fertilizer production process:

1. The first step is pollution-free fermentation: animal manure needs to be fermented before granulation or crushing before it can become organic fertilizer. The organic fertilizer granulator produced by our factory can handle animal manure such as chicken manure, cow dung, pig manure and sheep manure,etc.

2. The second step with mixing and high-humidity and semi-wet pulverization and mixing:in the automatic batching system, the materials after the composting and the inorganic fertilizers such as N/P/K and other additives and other additives are passed through the material pulverizer and the horizontal type according to a certain ratio.the vertical crusher is used to crush the animal manure compost; the continuous automatic batching system is suitable for the dynamic measurement of organic fertilizer raw materials. And batching control; the mixing operation is equipped with a two-shaft continuous mixer.

3. Granulation system: The material is granulated by a new organic fertilizer granulator. After granulating, the granulars will be dried to remove the extra 20% moisture content before packing into bags.

Gypsum granulating production line:

The disc granulating production line is used for making fresh chicken, pig, cow dung, organic matter, municipal garbage and sludge into fertilizer. They do not contain any chemical ingredients, while chickens and pigs have poor digestion ability and can only consume 25% of the nutrients. Ingredients, and the other 75% of the nutrients in the feed are discharged with the feces, so that the dried products contain nitrogen, phosphorus, potassium, organic matter, amino acids, proteins and other ingredients.

Organic fertilizer granulating line including fertilizer crusher, fertilizer mixer,fertilizer screener,fertilizer disc granulator,rotary drum dryer for fertilizer,fertilizer packing machine.

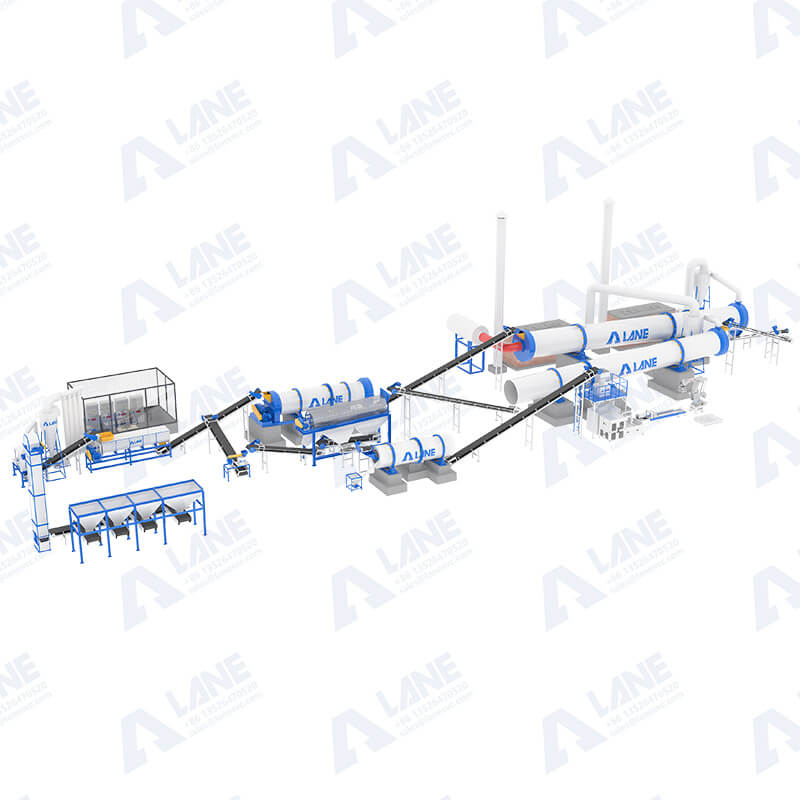

compound fertilizer production line:

1, the compound fertilizer production line process including: automatic batching system – pulverizer equipment (optional) – mixer – rotary drum granulator – dryer – cooling machine – screening machine – fertilizer coating Machine – automatic packaging and belt conveyors.

2. The drum granulator body is made of special rubber sheet lining or acid-resistant stainless steel lining, which realizes automatic mites and de-tumor, eliminating the traditional scraper device. The machine has the characteristics of high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life and convenient operation and maintenance.

3. Rotary drum granulator, which is equipped with steam, gaseous ammonia or phosphoric acid or nitrogen solution, phosphorus ammonia slurry, heavy calcium slurry, and chemical compounding and heating compound fertilizer granulation process in the cylinder; or The cold granulation process of the compound fertilizer supplemented with a small amount of water. The material to be granulated is passed through the rotary motion of the cylinder, and the rolling body rotates in the cylinder body, and is condensed into a ball under a certain humidity and temperature to complete the ball making process.

Chemical fertilizer granulation line:

The double roll granulator is designed with non-drying granulation, normal temperature process. It is suitable for granulation of various raw materials such as compound fertilizer, medicine, chemical feed, coal, metallurgy, etc., Our double rollder granulator can also produce compound fertilizer of various concentrations and various types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.).

Specially with good performance for single raw material: rare earth, ammonium bicarbonate, ammonium sulfate, ammonium chloride, potassium chloride, phosphate fertilizer, monoammonium, potassium sulfate, salt and other raw materials.

Compound fertilizer: binary, ternary, nutrient content 17.3-53% of various proportions of compound fertilizer, organic-inorganic compound fertilizer, bio-organic fertilizer, municipal sludge, domestic waste organic fertilizer, blended fertilizer.

BB fertilizer mixing line:

BB fertilizer mixer adopts positive and negative reversal, through special internal screw mechanism and unique three-dimensional structure for material mixing and output.The feeding system does not store materials, the mixing system is evenly mixing in the mixer, and the electronic control system. Manual, automatic.The equipment has the characteristics of low price, small floor space, large output and even mixing.

The complete BB fertilizer mixing line is mainly including the following equipment: storage silo; feeder; metering scale; mixer; large dip belt hoist; quantitative packaging machine; automatic sewing machine; finished conveyor belt conveyor; computer control system. The process is as follows: storage system–feeding system–metering system–conveying lifting system–mixing and mixing–automatic packaging and sewing package– finished belt transportation–computer control system.

The BB fertilizer equipment has various specifications, and the output per hour is 7-9T, 10-14T, 15-18T, 20-24T, 25-30T, etc.; according to the mixed materials, it is divided into 2-8 kinds of materials.

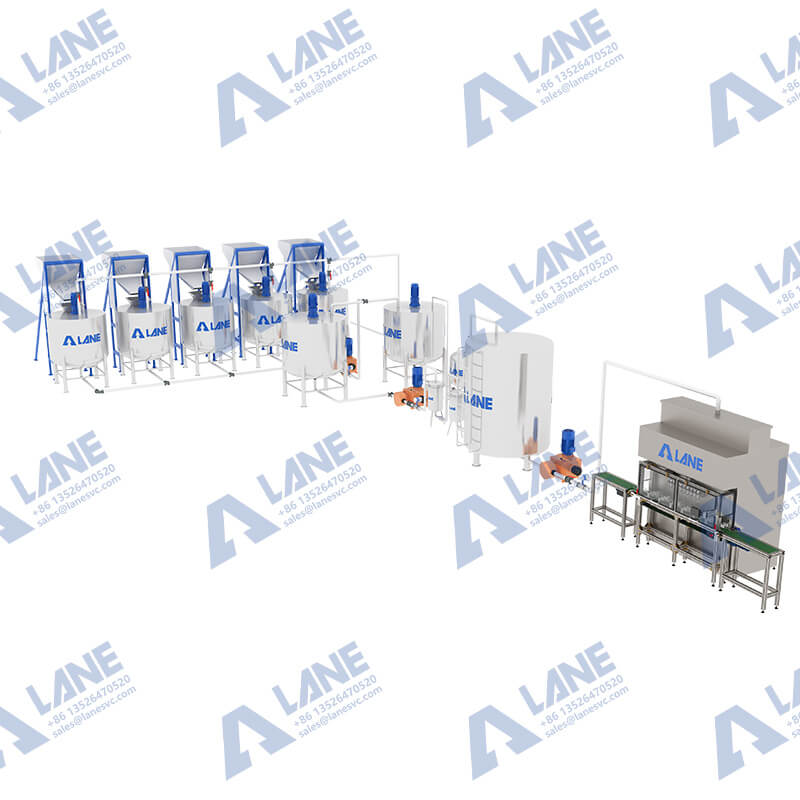

Liquid fertilizer production line

The flow of liquid fertilizer production line is as follows:

Automatic batching system: weigh and convey raw materials accurately according to the formula.

Mixing equipment: evenly mix the liquid nitrogen, phosphorus, potassium and other raw materials.

Dissolving equipment: dissolve solid or concentrated liquid raw materials.

Reactor (optional): used for chemical reaction to generate the required nutrients.

Filtration equipment: removing impurities to ensure the purity of liquid fertilizer.

Storage tank: to store and maintain the stability of liquid fertilizer.

Automatic packaging machine: filling and packaging liquid fertilizer.

Conveyor system: connects all parts of the production line to improve efficiency.

The equipment is made of stainless steel with automatic control system (PLC), realizing energy saving, environmental protection and efficient production.

Leave a Messages