Solid Granulating Method for Compound Fertilizer Production Line

Having a better understanding of the compound fertilizer production line process plays very significant role for the customers investment and compound fertilizer manufacturing. Currently the main production methods of granular compound fertilizer are slurry method, solid granulating method, melting method, etc. Now we will give a brief introduction of the most commonly used solid granulating method.

Brief Introduction of Solid Fertilizer Granulating Method

The solid granulating method uses single base fertilizer like urea, ammonium chloride, ammonium sulfate, potassium chloride, etc. as raw materials according to a certain proportion to mix together(mainly determined by the local market demand and soil detection results).

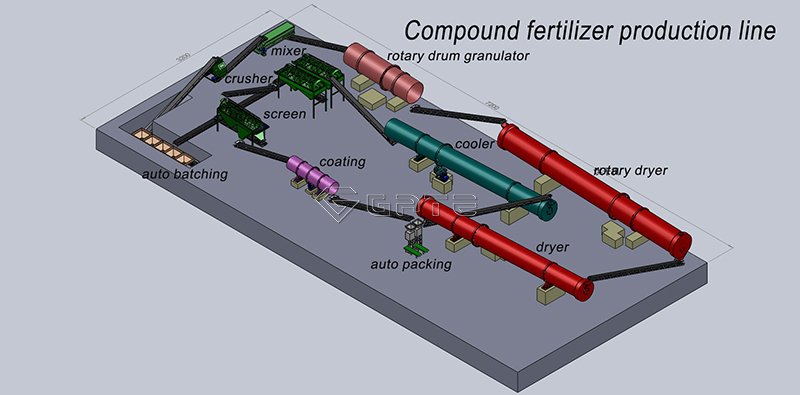

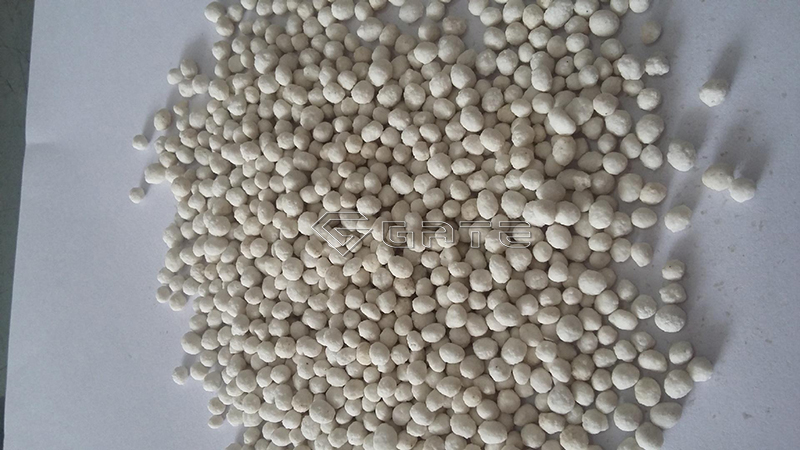

Then uniformly stirs the well-allocated raw materials with our fertilizer mixing machine, and crushes them to a certain fineness. Next is the major and essential step—-granulating, here you need the rotary drum granulating machine. The materials are send to the granulating machine by the belt conveyor, and through a series of humidifying, heating process to agglomerate and form particles. Here the particles are just the semi-finished products, they also require further processing including drying, screening, cooling and packaging. Finally after all these procedures, you can get the high quality compound fertilizer products.

Benefits of Solid Granulating Method

1. The raw materials are easy to get by adopting the solid granulating method, and the processing is relatively simple.

2. Advanced and mature technology for industrial compound fertilizer production.

3. Less investment, low production cost and high returns.

4. Belongs to second processing of the base fertilizer, so almost no environmental pollution problems existed.

Leave a Messages