Operating steps and precautions for the disc fertilizer granulator

What are the steps for using the pan granulator?

1. Adjust the stirring structure of the gua knife. The clearance of the gua knife from the bottom of the plate is generally 5-10mm. After adjustment, tighten the bolts;

2, adding materials, generally limited to the material does not overflow the disc granulator of the pelletizing machine;

3. Open the sprinkler valve to humidify the material. The degree of humidification is related to the nature of the material and the rotational speed of the disc;

4. Discharge, when the size of the disc granulator has reached the required level, stop and discharge.

What are the precautions for the operation of the disc granulator?

1. It is strictly forbidden to enter with iron in the material.

2. The disc granulator should be smeared with yellow dry oil before starting the gear.

3. The gear oil must be added once before use, and the gear oil can be replaced every four months.

Can you introduce the advantages of the disc granulator?

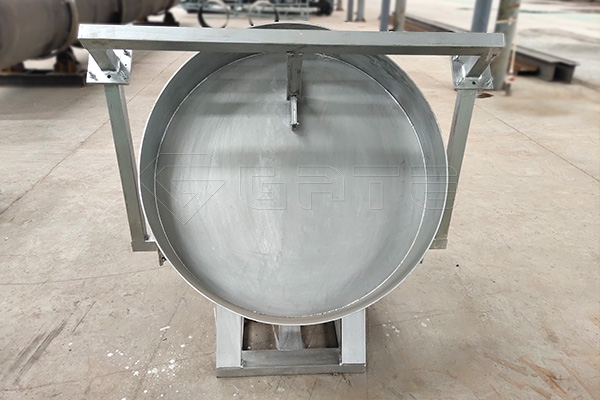

The disc granulator has an overall circular arc shape and the granulation rate can reach over 93%. The granulation tray has three discharge ports, which facilitates intermittent production operations, greatly reduces labor intensity and improves labor efficiency. The reducer and the motor are driven by a flexible belt, which makes the starting smooth, slows the impact force and improves the service life of the equipment. The disc bottom of the disc granulator is reinforced with a plurality of radiant steel sheets for durability. The thickened, weighted, and sturdy base design eliminates the need for anchor bolts for smooth operation. The main gear of the granulator is quenched by high frequency, and the service life is doubled. The granulated face plate is lined with high-strength steel for corrosion resistance and durability.

Leave a Messages