NPK Fertilizer Production Line

NPK fertilizer production line or NPK fertilizer production plant can use various raw materials like Urea, DAP, MOP, KCL,TSP, SSP, ammonium sulphate, phosphate, gypsum, lime, or other materials. our npk fertilizer manufacturing plant can produce high quality NPK Compound fertilizer , Capacity: 1-50 ton/hour npk fertilizer manufacturing process, Application: npk compound fertilizer production line, npk fertilizer granulator machine,npk fertilizer manufacturing equipment, Advantage of NPK fertilizer: large capacity, high automation, high granulating ratio, low energy consumption, friendly environmental protection

Get price Send us

Composition of NPK fertilizer production line

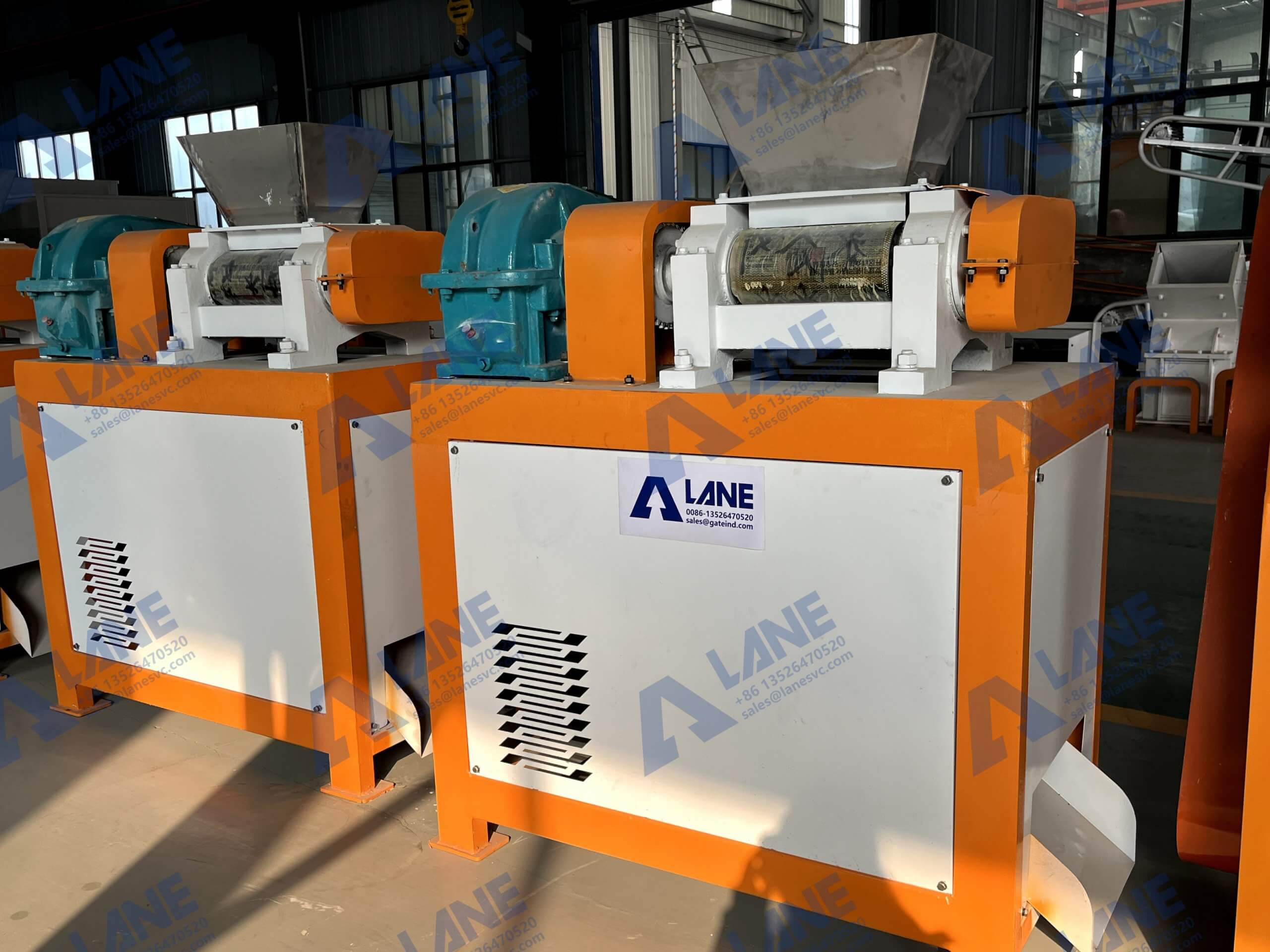

The NPK fertilizer production line includes automatic batching machine, mixer machine, rotary drum granulator or double roller granulator, belt conveyor, rotary dryer, rotary cooler, rotary screen, rotary drum coating machine, automatic packing machine and chain crusher.

We provide complete sets of equipment for NPK compound fertilizer production and solutions for our esteemed customers!

| Product name | Machine parameters | Speed | ||

| Dynamic Batching System | PVC drive belt: width 0.5m, length 2m | 1.1-2.2KW | SBD series reducer | 1450r/min |

| Vertical Crusher | 1-12t/h | 7.5-37KW | Crushing fineness: 0.5-5mm | 1450r/min |

| Horizontal Mixer | 1-40t/h | 7.5-55KW | ZQ series reducer | 1450r/min |

| Double Roller Granulator | 0.8-4.5t/h | 11-30KW | ZY series reducer | 1450r/min |

| Rotary Drum Drying Machine | 1-25t/h | 5.5-22KW | ZQ series reducer | 1450r/min |

| Cooling Machine | 1-20t/h | 5.5-22KW | ZQ series reducer | 1450r/min |

| Rotary Screen Machine | 1-23t/h | 3-7.5KW | ZQ series reducer | 1450r/min |

| Rotary Coating Machine | 3-15t/h | 7.5-15KW | ZQ series reducer | 1450r/min |

| Rotary Packing Machine | 4-20bags/minute | 50Hz/60Hz/220V/380V | ZQ series reducer | 1450r/min |

Application of NPK Fertilizer Production Line

1. NPK fertilizer production line has wide adaptability to raw materials which can be urea, ammonium nitrate, ammonium sulfate, monoammonium phosphate(MAP), diammonium phosphate(DAP), single superphosphate(SSP), potassium chloride, potassium sulfate, gypsum, lime, etc. You can choose according to market demand and NPK fertilizer formulation.

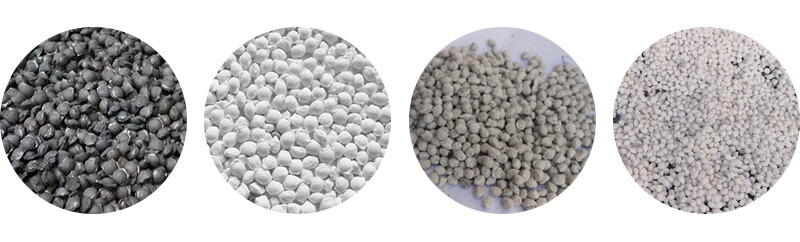

2. Rotary drum granulator NPK fertilizer manufacturing equipment can produce NPK compound fertilizer, organic fertilizer and organic compound fertilizer with the content of N, P, K ranging from 20-48%. It is mainly used for producing spherical particles with a diameter ranging from 1mm to 5mm.

Advantages of NPK Compound Fertilizer Production Line

1. Equipped with advanced fertilizer manufacturing technology. Can complete NPK fertilizer granulation all in one process.

2. Adopts advanced rotary granulator, granulating ratio is up to 90%, high intensity of granules.

4. Wide adaptability of raw materials, suitable for NPK compound fertilizer, pharmaceuticals, chemicals, fodder and so on.

5. High-quality, stable performance, low energy consumption, long service lifespan, easy maintenance and operation, etc.

6. High efficiency and economic returns, and the small part of feeding back material can be granulated again.

7. Adjustable capacity according to customers’ requirements.

8. Highly automatic and high precision. The batching machine system and packing machine are controlled by PLC computer to realize automation.

We have taken full consideration of user experience when designing and manufacturing fertilizer machines.

Process of NPK Compound Fertilizer Production Line

The process technology of NPK fertilizers is advanced and reliable. According to the compatibility of the three raw materials, NPK compound fertilizer in different percentage composition can be manufactured applicable for different requirements of soils and crops.

1. Mixing Process: the raw materials are put into mixer in strict accordance with the technical requirements of each raw material quantity. Then the conveying belt sends the materials to crushing machine.

2. Crushing Process: the crusher machine smashes lump materials into small ones that the fineness meets the required for granulation. Then the conveyor belt sends the materials to rotary drum granulator machine.

3. Granulating Process: there is a water pump to offer gas or steam and makes fertilizer particles forming easily. The solid fertilizer powder after granulation will rise by the rotation of the cylinder and scroll down under the effect of gravity. At the same time, according to the raw material quantity, add a certain proportion adhesives for granulation. After several times repetition of the same rotation, fertilizer materials gradually form. Next the conveying belt sends the materials to rotary drum drying machine and cooling machine.

4. Drying & Cooling Process: there are also draught fans to supply hot air and cold air to rotary dryer machine and rotary cooler machine respectively.

5. Screening Process: the qualified materials can be sent to packaging machine by bucket elevator, while others are conveyed back to crusher or granulator to be re-processed.

6. Fertilizer Coating: the conveyor belt sends the qualified granules from the second screen into the rotary coating machine from the higher end. With the rotation of the cylinder, powder or liquid are evenly coated on the surface of granules, which prevent caking, meanwhile increase the brightness and roundness of the granular. The machine is lined with polypropylene plate or stainless steel plate.

How to Produce the High Nitrogen NPK Compound Fertilizer?

To produce high nitrogen compound fertilizer, one important equipment is needed in the granulating process: the spraying system. The melting tank melt the urea and then spray the melted liquid into the granulating machine so that it will mix with powder phosphate fertilizer, potash fertilizer and other nitrogen fertilizer. Then with the help of the NPK fertilizer granulator, the liquid and other raw materials will be mixed and granulated. This production technology is used to produce compound fertilizer or complex fertilizer with high nitrogen content from 25%-45%.

If you have any other questions or needs, please feel free to contact us. We will provide you with the highest quality and most comprehensive service!

Leave a Messages