How to work the compound fertilizer production with rotary drum fertilizer granulator ?

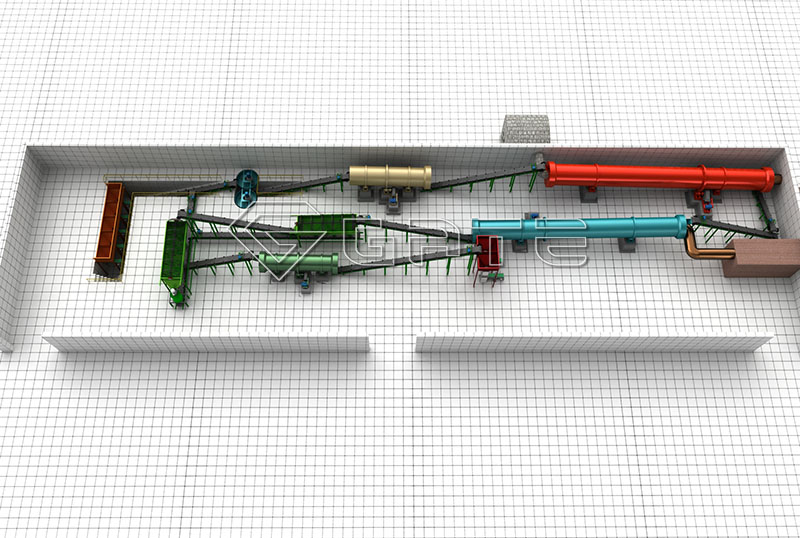

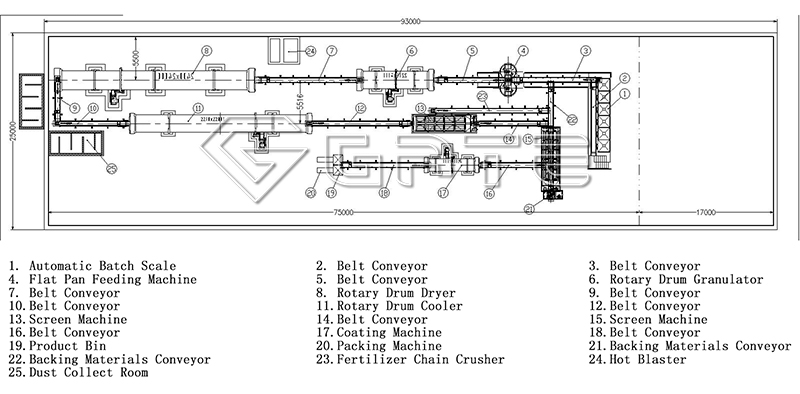

Having a better understanding of the compound fertilizer production process plays very significant role for the customers investment and compound fertilizer manufacturing. Currently the main production methods of compound fertilizer granules are slurry method, granulating method, melting method, etc. Now we will give a brief introduction of the most commonly using rotary drum granulating method.

Brief Introduction of Rotary Drum Granulating Method

The rotary drum granulating method uses single base fertilizer like urea, ammonium chloride, ammonium sulfate, potassium chloride, etc. As raw materials according to a certain proportion to mix together(mainly determined by the local market demand and soil detection results).

Then uniformly stirs the well-allocated raw materials with our fertilizer mixing machine, and crushes them to a certain fineness.

Next is the major and essential step—-granulating, here you need the rotary drum granulating machine. The materials are send to the granulating machine by the belt conveyor, and through a series of humidifying, heating process to agglomerate and form particles.

Here the particles are just the semi-finished products, they also require further processing including drying, screening, cooling and packaging. Finally after all these procedures, you can get the high quality compound fertilizer products.

Rotary drum granulator is a kind of molding machinery that can be made material into a specific shape. Rotary drum granulator is one of the key equipment in fertilizer plant line of compound fertilizer industry, applicable to cold and hot granulating as well as the mass production of high, low and medium concentration compound fertilizer.

Drum Granulator Brief Introduction

This machine barrel adopts special rubber lining or acid stainless steel lining, can realizes the automatic except scar, take off the tumor, cancel the traditional scraper device. The machine has high fertilizer particles rolling rate and good appearance quality, high corrosion resistance and wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc.

Rotary drum granulator inlets steam, gas ammonia or adds phosphoric acid or ammonia nitrogen, phosphorus ammonia solution slurry, coarse whiting slurry, completes the fertilizer granulation process of chemical reaction and heat within the cylinder; Or adds a small amount of moisture to finish the compound fertilizer granulation process. Feed the granulating materials through the rotation movement of the cylinder, the cylinder can produce roll rotation, sticking together into a ball in certain humidity and temperature, then the granular fertilizers finish forming process.

The Rotary Drum Type Pelleting Machine Features

1.High fertilizer particles rolling rate about 70%, less returning fertilizer created, can be re-granulated.

2.The steam heating to improve the material temperature, can make the material low moisture and improve the efficiency of dry.

3.Rubber engineering plastics as lining, not easy to stick, and anti-corrosion insulation effect.

4.Large output, low power consumption, low maintenance cost in npk fertilizer granulator machine.

Working Principle of the Rotary Drum Granulator

This drum granulator working principle is: the main motor drives the belt and pulley, through the reducer transmit to the drive shaft, install on the drive shaft of open gear and fixed on the body of the big gear ring gear, relative work. Materials are fed from the feed end into the cylinder internal. Under the effect of cylinder internal special structure, then granules, and finally runout by the discharge hole. Due to the materials are fed into the NPK drum granulator fertilizer, it can realize the mass production.

Drum Granulator Maintenance

The maintenance of the machine is an extremely important regular work, the operation and maintenance should be extremely close cooperation, and should have full-time staff on duty checks.

1. The baring is responsible for machine’s all loads all, so good lubrication has a great relationship for the bearing life, it directly affects the service life of machine and availability, and requirements into lubricating oil must be clean and the seal must be good, the machine’s main oil parts: (1) the rotation bearing, (2) roller bearings, (3) all the gears, (4) live bearing, sliding plane.

2. The newly installed tire is prone to loosen, should be check regularly.

3. Pay attention to each part of the machine, if working normally or not.

4. Pay attention to check the wear degree of easy wear parts, always pay attention to replace worn or damaged parts.

5. Chassis plane that puts activity unit should be out dirt and other materials to avoid serious accident .

6. If the oil temperature of bearing rises high, should immediately stop to check the reason.

7. If there is sound impact should immediately stop to check when the rotation gear in operation.

Installation Commissioning of Granulator Drum Fertilizer Machines for Sale

1. The device should be installed on the basis of a horizontal concrete, fixed with anchor bolts.

2. When installation should pay attention to the vertical and level of the main body.

3. Check each part bolt fastening after installation, the host storehouse door loosening.

4. According to the equipment the power configurate power and control switch.

5. After checking finished, can have a empty load test, then can be normal production.

Benefits of Rotary Drum Granulating Method

1. The raw materials are easy to get by adopting the solid granulating method, and the processing is relatively simple.

2. Advanced and mature technology for industrial compound fertilizer production.

3. Less investment, low production cost and high returns from compound fertilizer plant line.

4. Belongs to second processing of the base fertilizer, so almost no environmental pollution problems existed.

Leave a Messages