How to Screen Organic Fertilizer?

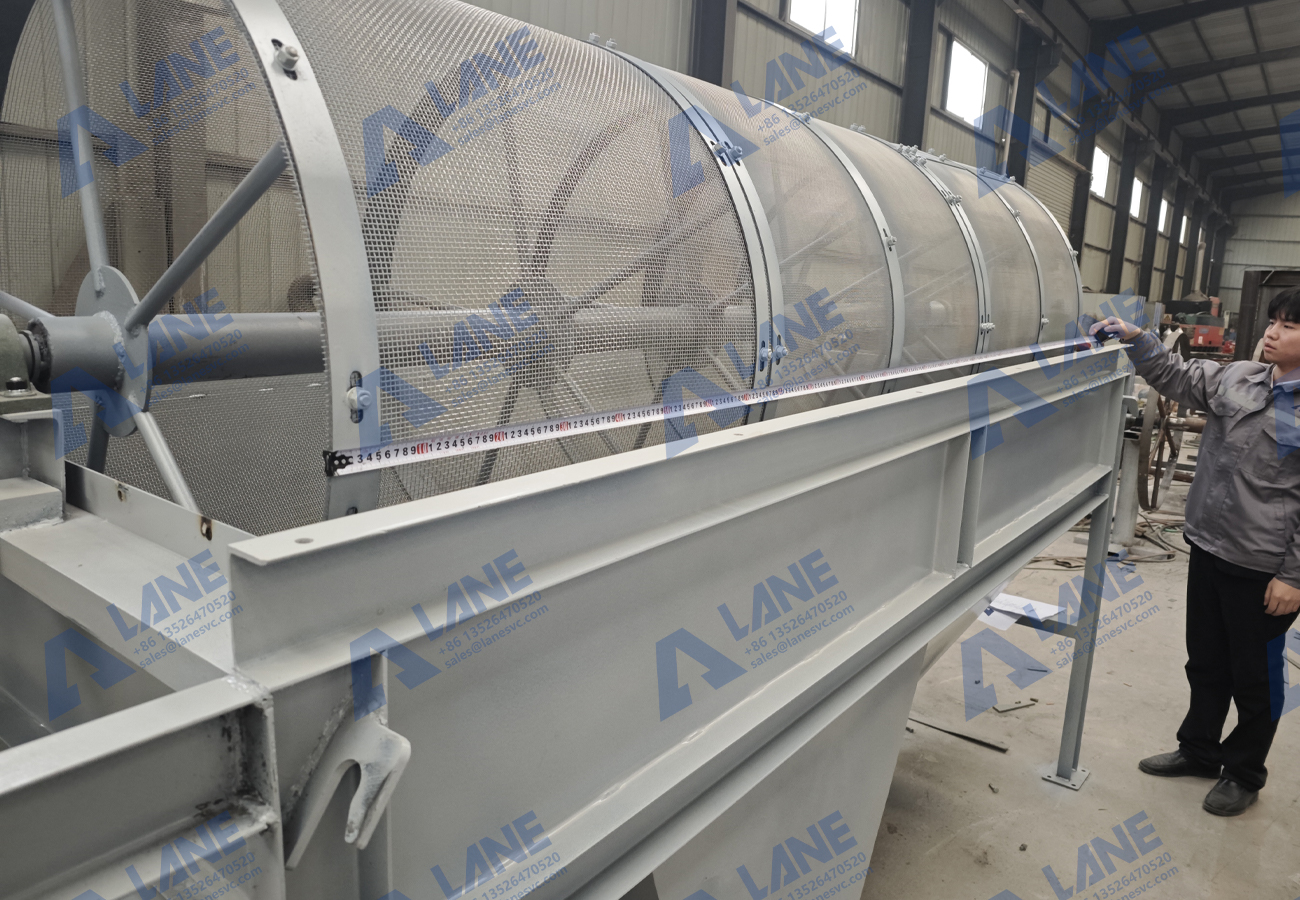

The rotary screen machine is a new type of self-cleaning special equipment for screening materials. It is widely used in the screening of various solid materials with a particle size of less than 300mm.Rotary screen machine has many characteristics such as high screening efficiency, low noise, small amount of dust, long service life, small amount of maintenance, and convenient maintenance.Rotary screen machine is a commonly used equipment in the production of compound fertilizer.

Working principle of rotary screen machine:

1. The rotary screen machine uses a gearbox type deceleration system to reasonably rotate the separation drum in the center of the equipment.

2. The central separation cylinder is a screen composed of several circular flat steel rings, and the central separation cylinder is inclined to the ground plane. During the working process of the drum screening machine, the material enters the drum net from the upper end of the central separation drum.

3. During the rotation of the separation drum, the fine materials are separated from top to bottom through the screen interval composed of circular flat steel, and the coarse materials are discharged from the lower end of the separation drum into the pulverizer.

4. There is a plate-type automatic cleaning mechanism in the rotary screen machine. In the separation process, through the relative movement of the cleaning mechanism and the sieve body, the sieve body is continuously “combed” by the cleaning mechanism, so that the sieve body is always kept clean during the entire working process, and the screen will not be affected by the blockage of the sieve holes.

If you need an organic fertilizer screening equipment, please contact us. Gate Heavy Industry is an environmentally-friendly high-tech enterprise specializing in the research and production of organic fertilizer and compound fertilizer equipment. If you have any questions about the equipment, we will arrange professionals to answer you in detail.

Leave a Messages