How to achieve the production of organic fertilizer in peanut shells in batches?

The main components of peanut shells are cellulose and lignin, which are not easily decomposed. Direct application to the soil will result in a decrease in the water retention capacity of the soil, and a large amount of heat will easily cause the seedlings when the peanut shell itself rots. The best way is to process it through organic fertilizer production equipment and turn it into organic fertilizer that can be completely absorbed by crops.

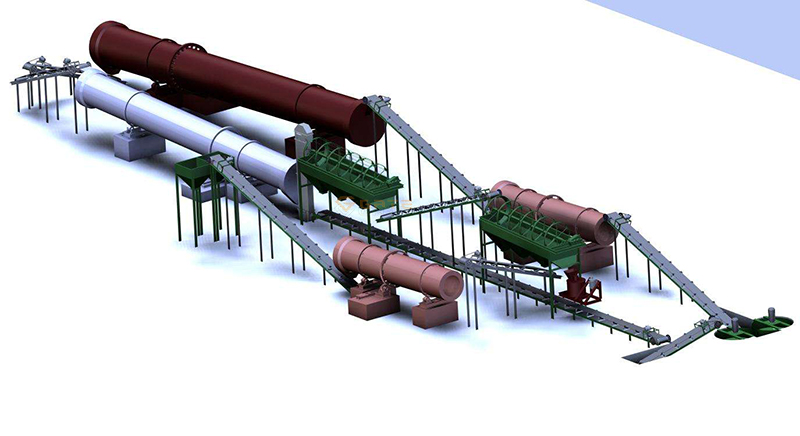

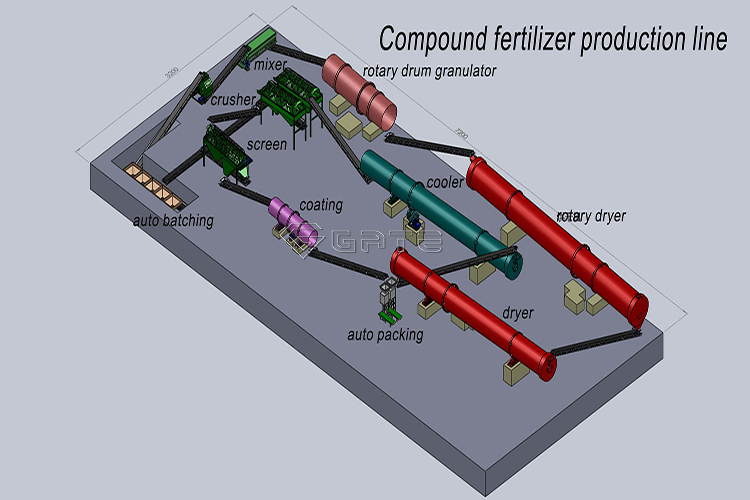

How does peanut shell become organic fertilizer? Then you need to understand the organic fertilizer production line. The process of organic fertilizer production line can be generally divided into: raw material ingredients, raw material agitation, raw material granulation, granule drying, granule cooling, particle grading, finished product coating, and final product packaging. Through these processes, the peanut shell becomes a fertilizer that can be directly used for agricultural plants. The fertilizer processed by the organic fertilizer production line is not only more beneficial to be completely absorbed, but also does not pollute the soil and cause environmental pollution.

Organic fertilizer production line workflow

1. Raw material ingredients: Urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium), potassium chloride (potassium sulfate) and other raw materials are equipped according to a certain ratio (according to Market demand and soil test results everywhere).

2. Stirring of raw materials: The mixer Stir the prepared raw materials evenly to increase the uniform fertilizer content of the whole fertilizer granules.

3. Raw material granulation: The uniformly stirred raw materials are sent to a granulator for granulation (a drum granulator can also be used, and an extrusion granulator can also be used).

4. Drying of granules: The granules produced by the granulator are sent to the dryer to dry the moisture contained in the granules, increasing the strength of the granules and facilitating storage.

5, particle cooling: After drying, the temperature of the fertilizer particles is too high, easy to agglomerate, after cooling, easy to bag storage, and transportation.

6. Granulation classification: The cooled particles by the cooler machine are classified, and the unqualified particles are pulverized and regranulated, and the qualified products are sieved out.

7. Finished coating: The qualified product is coated to increase the brightness and roundness of the particles.

8. Finished packaging: Store the granules that have been coated with the film, that is, the finished bag, in a ventilated place.

Leave a Messages