How can chicken manure be treated to become organic fertilizer?

The application of organic fertilizer processed by organic fertilizer equipment meets our search for green and organic food. Since the organic fertilizer processed by the organic fertilizer equipment is rich in nutrients and rich in organic matter, it can improve the soil. Most of the organic fertilizer processing organic fertilizer production materials are culture manure, crop straw, organic waste, sewage sludge, distiller’s grains, etc. These materials are wastes left in other occupations. These materials are usually accompanied by stench. When the nose smells, it will also breed fly worms. If it is not treated in time, it will form a certain pollution to the surrounding environment.

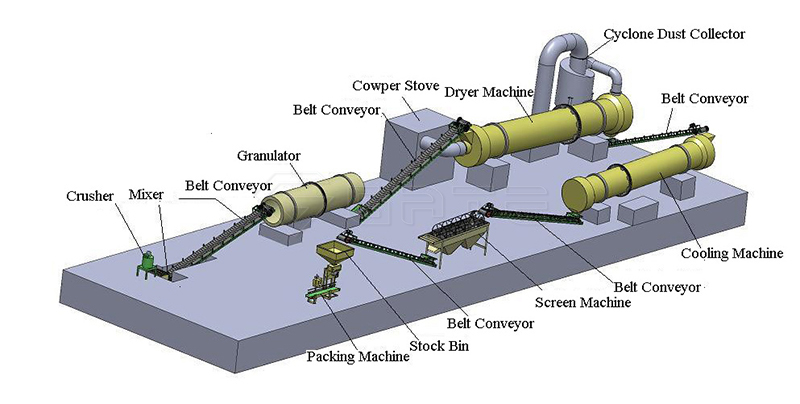

The chicken farm is the place with the most chicken waste. It is not only pungent, but also the treatment of chicken manure is a big problem. With the emergence of the organic fertilizer production line, the chicken manure has changed from waste to organic fertilizer. Waste is treasure. How to turn chicken manure into organic fertilizer? Then you need to process through the organic fertilizer production line. The processing flow is: turning machine fermentation—-grinder crushing—–mixer—-granulator—–dryer—–cooling machine—-screening machine- —The coating machine—-packaging machine.Through the processing of these columns, chicken manure becomes a product that is beneficial to crops and harmless to the environment.

Here, we will take a brief introduction of the granulator in the organic fertilizer production line—disc granulator.

The scope of the disc granulator

Disc granulator is suitable for various non-stick materials in powder, material or small pieces, such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc. Powder, granular or small block materials. Disc granulators can be widely used in gold processing plants, coal mining plants and chemical, infrastructure and mechanized foundry workshops. The machine has simple structure, convenient adjustment and superior performance. The disc granulator is suitable for materials with a particle size of not more than 50 mm, and is not suitable for conveying materials with high viscosity, not easy to flow, and materials with particularly good fluidity.

Factors affecting granulation of disc granulator

1, the fineness of raw materials

2, the amount of delivery

3, feeding position

4. Water content of semi-finished products

Leave a Messages