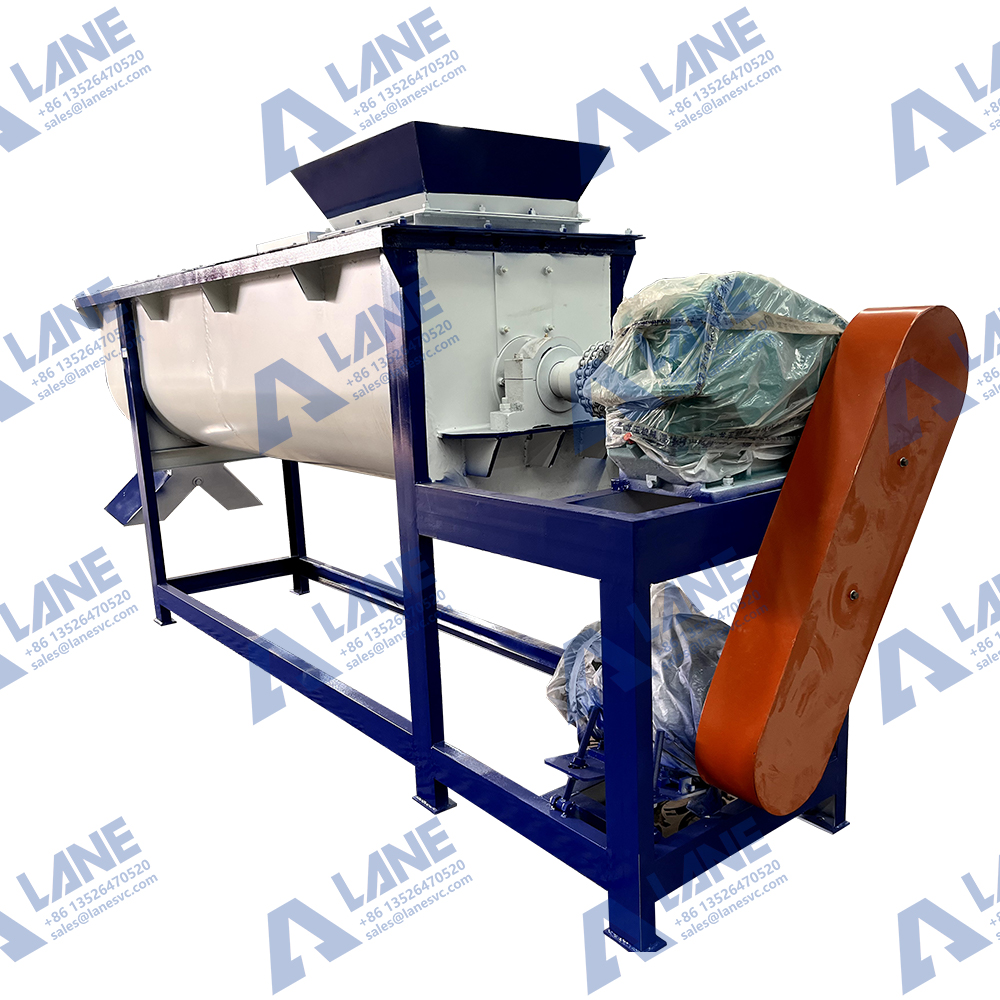

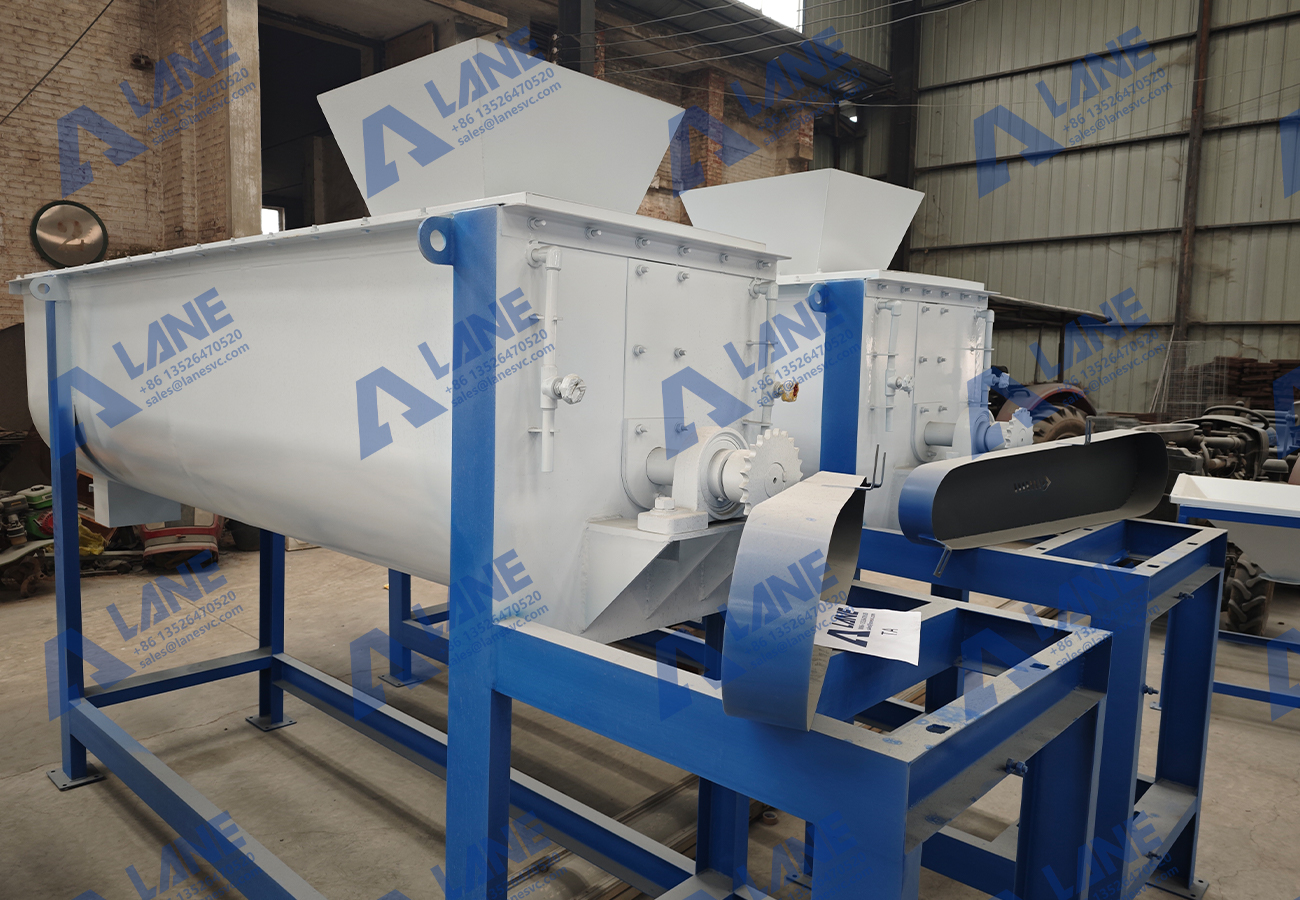

Horizontal Mixer for Uniform Mixing

Horizontal mixer is a new type of mixing equipment. It has fast mixing speed and high mixing uniformity. It can mix materials evenly with less residue. It is very suitable for mixing animal feed, concentrated feed and fertilizer.

Advantages:

1. The mixing speed is fast. It adopts single-shaft double-spiral belt mixing, the material moves as a whole, the speed is high, and the output is high. The average mixing time is 5-10 minutes.

2. The mixing uniformity is high, the material moves in multiple directions, the multi-layer spiral belt, the mixing has no dead ends, the uniformity is high, and the quality is good.

3. The maintenance rate is low. The bearings are at both ends of the mixer, and materials are not easy to enter. Equipped with a reducer, the maintenance rate is low.

4. One machine with multiple functions, very suitable for mixing animal feed, concentrated feed and fertilizer. It can also produce thermal insulation mortar, putty paste, plaster plaster, real stone paint, etc.

Structural features:

1. The horizontal mixer is a new type of high-efficiency mixing equipment, which is composed of a container, a spiral mixing blade and a transmission part.

2. It has a novel rotor structure without mixing dead angle, and the mixing is uniform and excellent;

3. The gap between the rotor and the casing can be adjusted, and the bottom is wide open or full length open, and the residual material is small;

4. Both ends of the machine body are designed with double layers to prevent material exposure at the two shaft ends. The action is more accurate and reliable, and the sealing performance is good. The machine is equipped with grease adding pipes. The overall structure is reasonable, the appearance is beautiful, and the operation and maintenance are convenient.

5. Spiral blades are generally made of double layers, and the outer spiral conveys materials from the center to both sides to form convective mixing.

The horizontal mixer can evenly mix powdered or granular materials such as feed, fertilizer, and grain. It has the characteristics of high efficiency, good mixing quality, short unloading time and low residual quantity. It is an ideal model for organic fertilizer, feed and other industries.

Leave a Messages