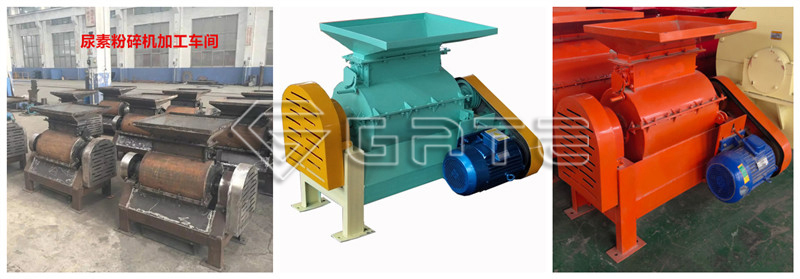

high capacity urea crushing machine for fertilizer manufacture

Urea crusher is mainly used for fine crushing operations, small urea crusher, this machine can crush a variety of single fertilizer, especially for harder materials. Urea crusher has simple and compact structure, good crushing effect, smooth operation and easy cleaning. Urea crusher is especially suitable for crushing hard materials such as monoammonium, diammonium and urea. Urea mill is an indispensable good equipment for compound fertilizer production line. and urea crusher is a crushing equipment designed to crush urea to meet the production requirements of high nitrogen compound fertilizer.

What characteristics does urea mill have?

1.Urea mill is simple in structure and easy to clean.

2.Urea mill operates smoothly, low noise, double roll urea mill, low vibration.

3.Urea mill is easy to operate, the size of grain size can be controlled by changing the screen.

How to maintain the urea crusher?

1, the bearings of the urea crusher often refuel.

2, the urea pulverizer is not used for a long time, the inside of the pulverizer must be cleaned, and the two rollers can be cleaned with a brush.

3. When the pulverizer is not working, cover the feed port to prevent foreign matter from entering the roller of the urea pulverizer.

4, urea crusher must be operated by a person, dedicated personnel maintenance.

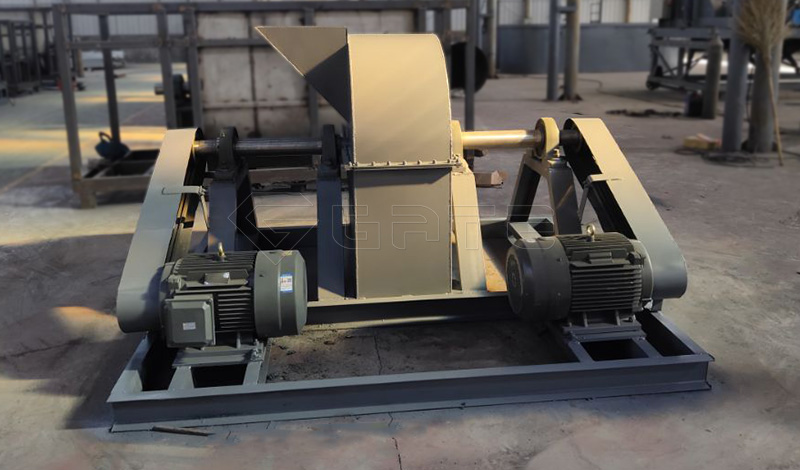

How does the urea pulverizer smash the material?

The urea pulverizer mainly uses the grinding and shearing of the gap between the drum and the concave plate at high speed. The size of the gap of the urea pulverizer determines the degree of material pulverization. After the urea enters the body, it hits the body wall and the baffle to be broken, and then passes through the drum and the concave plate. The rack between them is ground into a powder. The gravure gap of the urea pulverizer is adjusted by the adjustment mechanism in the range of 3-12 mm.

Leave a Messages