Flat die granulator can be used for organic fertilizer granulation

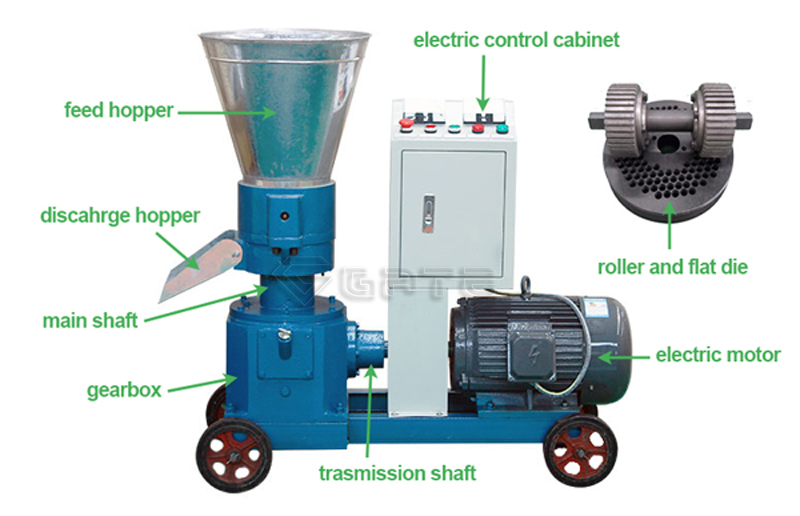

The flat die granulator is the latest technology product developed from the design and production experience of organic fertilizer processing equipment, and has obtained the national utility model patent. It is used for granulating various organic fertilizers after fermentation, and breaks through the conventional organic granulation process. The flat die granulator does not need to dry and pulverize the raw materials before granulation, and can directly process the cylindrical particles by directly compounding. Save a lot of energy.

The organic fertilizer processed by the flat die granulator is mainly derived from plants and/or animals, and is applied to the soil to provide carbonaceous materials whose plant nutrition is its main function. It is processed by biological materials, animal and plant wastes and plant residues, eliminating toxic and harmful substances and enriching a lot of beneficial substances. The organic fertilizer processed by the flat membrane granulator not only provides comprehensive nutrition for crops, but also has fertilizer effect. Long, can increase and update soil organic matter, promote microbial reproduction, improve soil physical and chemical properties and biological activity, is the main nutrient for green food production.

Features of flat die granulator

1. The produced particles are cylindrical.

2, the organic content can be as high as 100%, to achieve pure organic granulation.

3. No need to add adhesive when granulating the flat die granulator.

4, the particles are strong, can be sieved after granulation, reducing drying energy consumption.

5. The machine is equipped with Φ1.5-Φ20mm multi-aperture molds to adapt to different materials granulation to achieve the best benefits.

Precautions of flat die granulator

1. There should be no hard objects such as stones and iron blocks in the raw material of the flat die granulator to prolong the service life of the bearing.

2. It is forbidden to contact the platen and the template during granulation.

3. If the particles are broken or not pressed properly, the crude fiber material formula should be reduced to less than 50%.

4. When the flat die granulator is granulated, there is no granulation or no discharge. The membrane should be removed, and after the hole is opened, the fiber material can be added to restart the granulation.

Leave a Messages