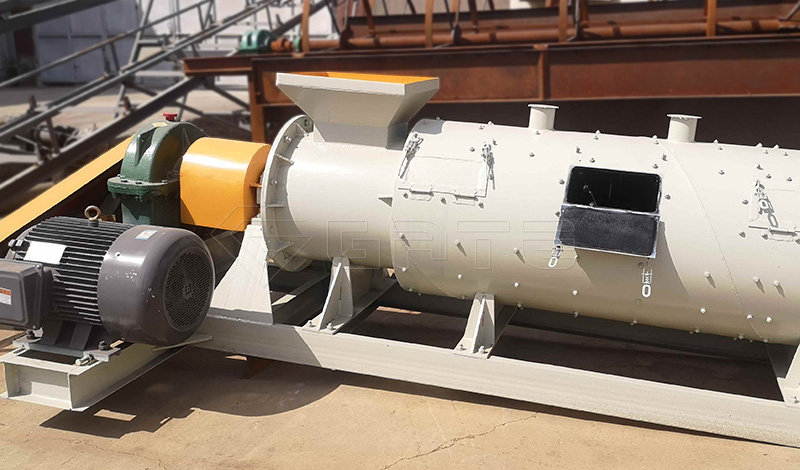

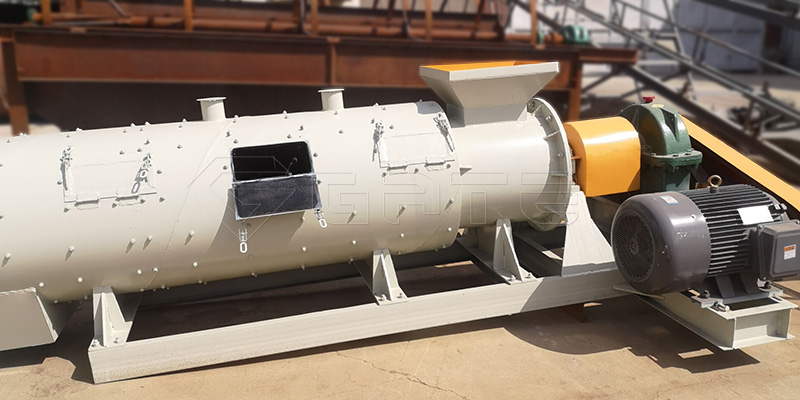

Factory supply Organic Fertilizer machine manufacturer Mixing Granulator

What are the technical parameters of the organic fertilizer mixing granulator machine manufacturer?

| Model | JCZ-60 | JCZ-80 | JCZ-100 |

| Power | 37KW | 55KW | 75KW |

| Capacity | 1-2 t/h | 2-4 t/h | 5-8 t/h |

| Dimension | 4100*1600*1150mm | 4250*1850*1300mm | 4700*2350*1600mm |

| Installation Angle | 2°-2.5° | 2°-2.5° | 2°-2.5° |

| Inlet Moisture Content | 20%-40% | 20%-40% | 20%-40% |

| Inlet Materials Size | 50 mesh | 50 mesh | 50 mesh |

What are the characteristics of organic fertilizer machine manufacturer mixing granulator?

1. High granulation rate, dense granularity. The ratio can be 90% above

2. Wet raw materials are available processing, no need drying before organic fertilizer mixing granulator machine manufacturer granulating

3. No binder need to add, materials inside will grow inlaid with each other under certain force.

4. Perfect ball shape fertilizers, moisture 20%-40%

5. Heavy seamless steel pipe ensure stable organic fertilizer machine manufacturer mixing granulator running

Can you tell us about the advantages of organic fertilizer mixing granulator?

1. Widely raw materials processing, especially wet raw mateirals

2. Energy saving, can be screened directly after Organic Fertilizer machine manufacturer Mixing Granulator Manufacturer granulating

3. High granulating rate, 90% above in Cow Manure Organic Fertilizer Mixing Granulator.

4. Hard granules in ball shape, good performance

5. Stable machine running, easy operating and maintain

How does the organic fertilizer mixing granulator work?

Composted materials can be sent to Chicken Waste Organic Fertilizer machine manufacturer Mixing Granulator with mixing. After materials enter into the machine through the feeding inlet, by the high speed rotating mechanical stirring force and aerodynamic force thereof, the materials are mixed, granulated, spherified and densified in the machine, achieving the aim of granulation. The formed granules are pushed out in the other end of Organic Fertilizer machine manufacturer Mixing Granulator Supplier.

The diameter of the produced granules can be controlled by adjusting the quantity of the raw materials and rotating speed of main shaft. The less the raw materials mixed and the higher the rotating speed, the smaller the granulated fertilizer.

Leave a Messages