Brief introduction to the structure of the organic fertilizer stirring granulator

The tooth stirring granulator is mainly used for granulation of all kinds of organic materials after fermentation, which breaks through the conventional granulation process. The machine does not need to dry the materials before granulation, and can process spherical particles directly after crushing, saving energy and high pelletizing rate at the same time.Organic matter content up to 97 above, achieve pure organic granulation, stirring teeth granulation machine granulation without adding binder.

Technical parameters of gear – stirring granulator

| Model | Power

(kw) |

Capacity

(t/h) |

Rotate Speed | Drum Size (mm) | Granule Diameter | Dimension(mm) | Granulate Ratio | Angle | Drum Rotate Speed |

| GTZM-60/120 | 37+7.5 | 1-3 | 1450r/min | Φ1200*6000 | 3-5 mm | 6600*1800*2000 | >96% | 2-2.5° | 17 r/min |

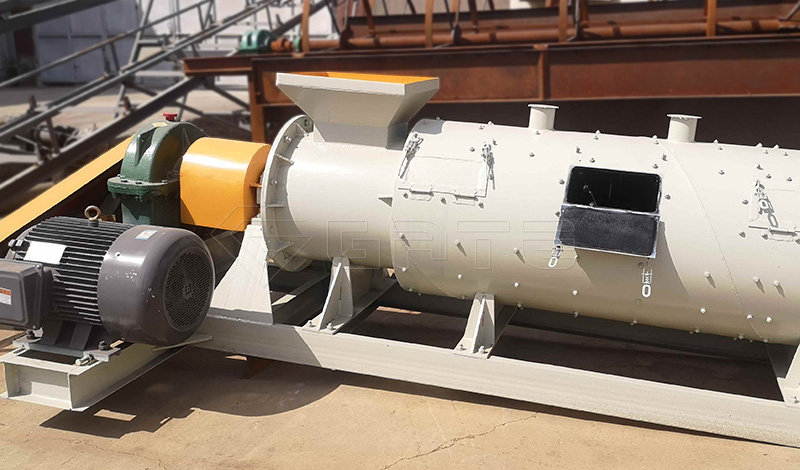

Gear – stirring granulator is composed of motor, transmission, rotor, cylinder and frame

1. GT series national standard motors are adopted, featuring strong power, energy-saving, reliable quality and overload operation.

2, gear stirring granulator reducer internal use of special materials, processed by special technology, gear stirring granulator with high bearing capacity, smooth operation, durable parts, safe and reliable work characteristics.

3, tooth stirring granulator rotor is divided into three parts: (1) shaft (2) stir teeth (3) stir tooth head.

4, the shaft is divided into three sections: (1) mixing section (2) granulating section (3) polishing section.The big shaft is made of special materials.The gear stirrer is made of special material, hard and wear-resisting, and can be adjusted. The gear stirrer head is made of alloy steel.

5, gear stirring granulator cylinder is divided into three parts: feed mixing section, granulation section and polishing section.

Gear prilling machine advantage

1. Compared with the natural aggregate granulator (such as rotary disc granulator and rotary drum granulator), the gear stirring granulator has a concentrated particle size distribution and is easy to control.

2, gear stirring granulator high efficiency, easier to meet the requirements of mass production.

3, gear stirring granulator spherical particles into grains after no acute Angle, so the powder rate is very low.

Leave a Messages