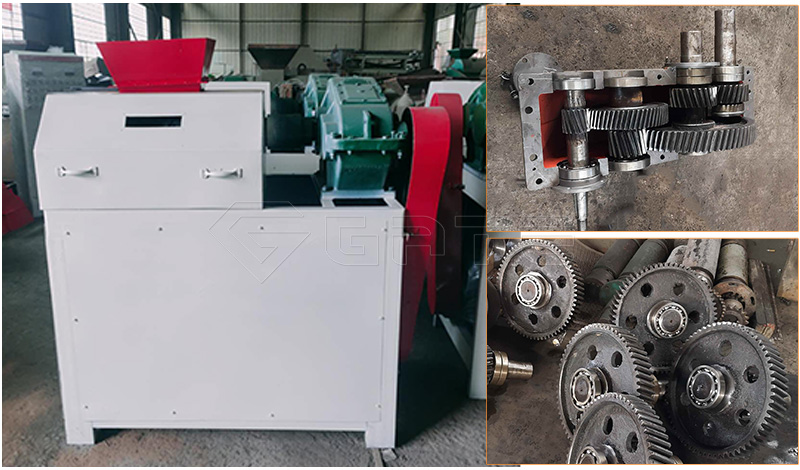

Brief introduction of the roller fertilizer granulator

The roller fertilizer granulator is produced by a non-drying normal temperature process, with one molding, and the output is 1-1.5 tons/hour and 1.5-3 tons/hour. The equipment has low investment, quick effect and good economic benefits. The raw material has wide adaptability and is suitable for granulation of various raw materials such as compound fertilizer, medicine, chemical industry and feed, and the product has high granulation rate. The roller extrusion granulator can produce various concentrations, multiple types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.) compound fertilizer. In particular, the granulation of rare earth, potash and ammonium bicarbonate series compound fertilizers has filled the domestic gap and is at the leading level in China.

Installation and commissioning of the roller fertilizer granulator:

1: After the extrusion granulator arrives at the factory, the granulator is used as the main machine, according to the number of units, and installed in accordance with the process flow chart to find the elevation and horizontal placement. The machine frame has a corner hole. Installed on concrete (the amount of solid vibration is not too large and does not require a strong concrete foundation).

2, the roller extrusion granulator This machine has been debugged before leaving the factory, still need to be debugged after trial use.

Process characteristics of the roller fertilizer granulator:

1. The counter-rolling granulator is first pressed into large pieces and then broken into granules, so that the device has large capacity, high particle strength and low energy consumption, and the roller extrusion is widely used abroad. A single machine can only reach 3-6 tons / hour, and the granulation strength is limited, the mold is easy to damage, the cylindrical pellets are produced, and the flowability is poor. The granulator raw material granulation does not need to add a binder.

2. The extrusion granulator acts as a binder during the granulation process. However, in the drying process, the water inside and outside the particle must be driven out, otherwise the fertilizer is easy to stick and agglomerate during storage. Dry granulation does not require additional additives. It only uses the intermolecular force of the material itself to simplify the process and reduce energy consumption. Extrusion granulation is the granulation of the material at normal temperature, compared with other methods. Requires drying measures such as fuel and gas.

Leave a Messages