BB fertilizer production line

BB fertilizer production line, measuring instrument name: multi-material automatic compounding and packaging machine, commonly used in the market: formula fertilizer production line, blended fertilizer production line, fertilizer production line, bb fertilizer production line. BB fertilizer equipment is a kind of chicken, pig feces as the main raw material, adding a certain amount of nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, magnesium sulfate, ferrous sulfate and other substances, rice bran, yeast, soybean meal and sugar fermentation for a certain period of time as a biological bacteria, Under the action of sulfuric acid, mixed fermentation produces equipment for biological fertilizer.

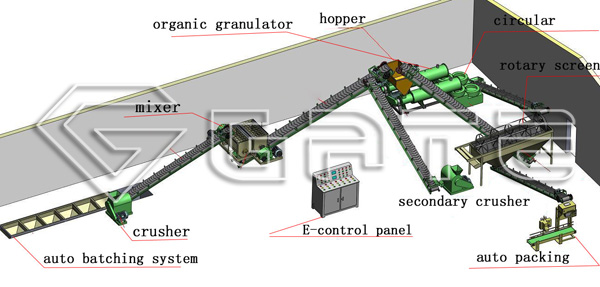

Production process of BB fertilizer production line

Computer PLC control system → automatic proportional batching material → bevel scraper lifting → drum mixing → weighing machine storage bin configuration mix → quantitative packaging (10-50kg / bag) → conveying and sewing → finished granulation storage.

Why choose our BB fertilizer production line?

1. It adopts pit type batching and cumulative weighing type to facilitate the transportation and transportation of raw materials, convenient operation, labor saving and labor saving.

2. Adopting German Siemens PLC centralized control system, the whole production process is fully automated.

3. Large capacity, 10 tons to 30 tons per hour, more suitable for large-capacity production lines.

4. Can be customized according to different requirements of customers.

BB fertilizer production line features:

1. The equipment has a small footprint (25~~50 square meters) and low power consumption (the power of the whole set of equipment is less than 10 kW/hour);

2, adaptability: suitable for a variety of harsh site environment.

3, using two-stage anti-shock processing, multi-stage filtering technology, accurate measurement, high precision;

4, easy to manage: high-speed 485 communication interface, optional communication system, production line main control room can monitor the operating status of each component, convenient connection with printers, computers, can store 20 kinds of formulas, truly realize modernization of production management.

5, the process is good: drum type mixing, single bucket lifting, does not damage the original particle shape of the material, and prevents the segregation phenomenon of the finished product after mixing; batch batch mixing mode, high mixing uniformity.

6. The actuator adopts pneumatic drive, two-stage feeding, independent measurement and accumulative measurement of various materials, and the production speed is fast;

7. The control system has automatic zero tracking automatic tare weight, coarse metering and drop automatic compensation, and overshooting automatic measurement correction fault alarm;

BB fertilizer production line scope:

1. In fertilizer, chemical, feed, cement and other industries

2. a variety of non-stick powder, granular material ingredients, mixing, quantitative packaging.

Working process of BB fertilizer production line

1. We should determine the type of raw fertilizer for the batch (2-6). Manually place the materials into each stock library.

2. The raw material boxes are then discharged into the weighing hopper in order of weight ratio according to the automatic accumulation type materials.

3. After completing the batching of all materials, the weighing bucket will open the material leaking door and feed the material into the drum rotating mixer through the belt conveyor. At the same time, the batching system continues to start a new round of ingredients.

4. After the mixing is completed, the mixed materials are transported to the weighing and packaging silo, and the weighing, packaging, conveying and sewing processes are completed to complete the batching operation. Then mix in batches and cycle through them.

Leave a Messages